Products

Contact Information

Address: No.9 Luxing Avenue, Luxing Industrial Park, Guangshui City, Hubei Province

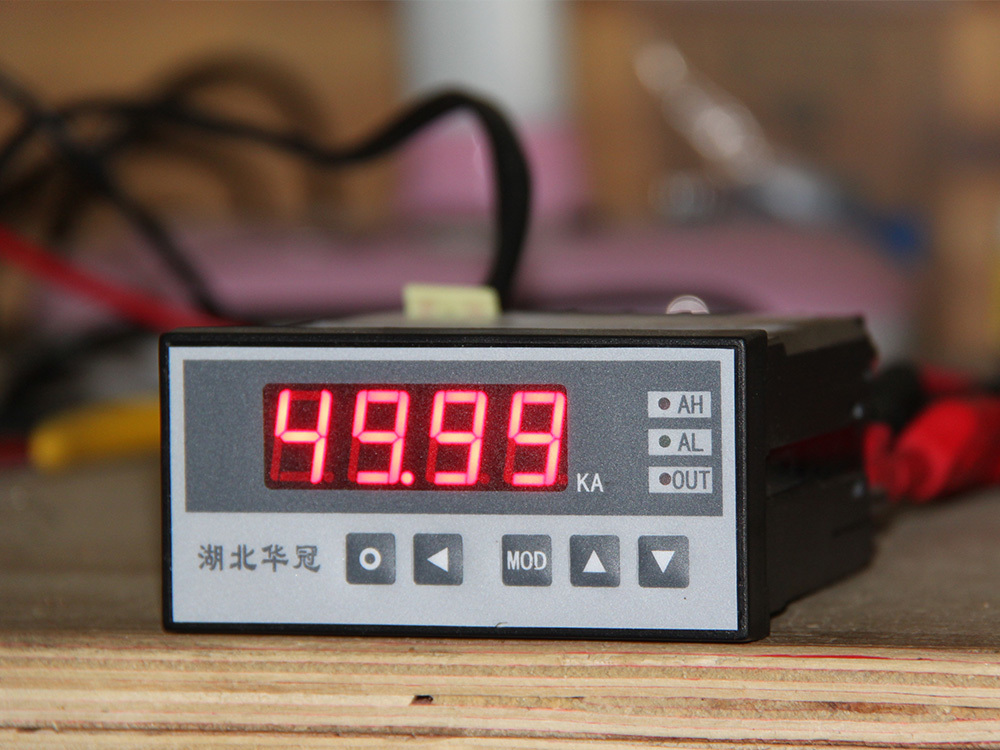

Countercurrent measurement and control device

Classification:

The KDA-N countercurrent measurement and control device is composed of a special countercurrent sensor, a countercurrent detector and a paperless recorder. It has a forward current measurement, a reverse countercurrent protection function and a forward overcurrent protection function. It is a countercurrent protection device that effectively prevents accidents caused by countercurrent from expanding.

Email:

Product Details

1. Overview

The KDA-N countercurrent measurement and control device is composed of a special countercurrent sensor, a countercurrent detector and a paperless recorder. It has a forward current measurement, a reverse countercurrent protection function and a forward overcurrent protection function. It is a countercurrent protection device that effectively prevents accidents caused by countercurrent from expanding. When the rectifier unit works normally, the measurement and control system can realize the current measurement function. Once the rectifier unit has a sudden fault and generates a countercurrent, the measurement and control system will detect the size of the countercurrent in time, provide signals for the overcurrent protection system through the countercurrent controller, cut off the network side control protection trip circuit, prevent major accidents, and record the time and process of the accident for post-analysis.

2. countercurrent detector features:

The reverse flow controller is divided into two parts: signal judgment and paperless recording. The KDA-N reverse flow sensor is composed of two sets of independent circuits. When the two sets of circuits detect negative current, the output is negative signal. Only when the two input signals are negative signals at the same time and the sum reaches the set trip value, the reverse flow controller can not be tripped, this way of signal processing avoids malfunction. The paperless recorder has rod diagram and curve recording, which can record the occurrence time of the fault, record the change curve of the current signal when the fault occurs, and provide evidence for the reverse flow fault search.

Next article

Related Products

Production strength

Message consultation

Company Address

No.9 Luxing Avenue, Luxing Industrial Park, Guangshui City, Hubei Province

Focus on us